SSI Blog

-

Thermoforming Products

-

Sustainable Plastic Manufacturing with Thermoforming

-

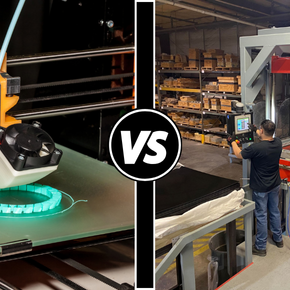

3D Printing & Thermoforming

-

Fiberglass Vs. Plastic & When to Choose Thermoforming

-

Thermoforming Polycarbonate vs. PETG vs. Acrylic: Finding the Best Clear Plastic for Vacuum Forming

-

Composite Plastics: Considerations for Thermoforming

-

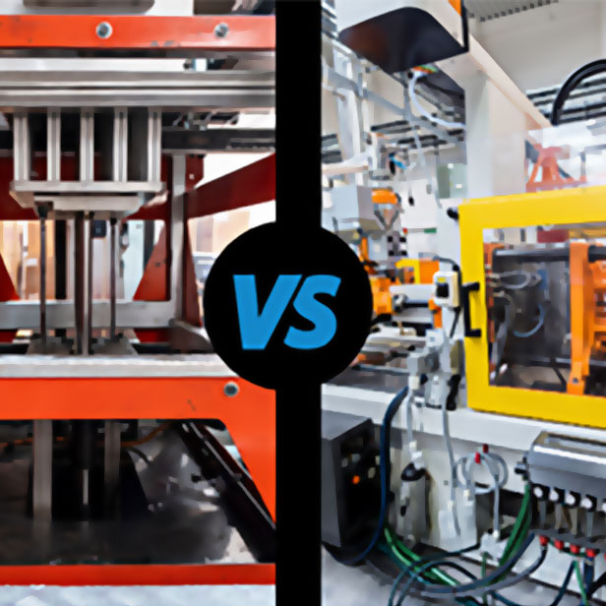

Thermoforming vs. Injection Molding: Cost, Lead Times & More

-

Thermoforming Materials: 10 Examples of Plastic Options

-

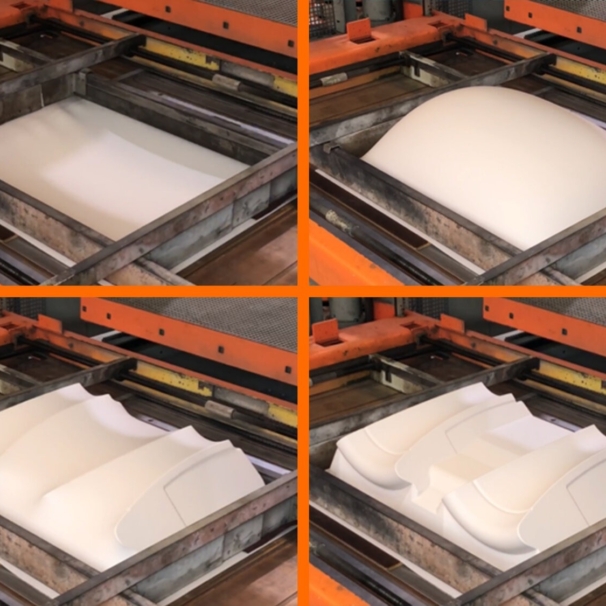

Plastic Forming Types: Manufacturing and Molding Methods

Start Your Project with Us

Whether it’s a unique design or a complex project, we have the expertise to bring your vision to life. Reach out to us and we’ll get back to you in just 1 business day!

REQUEST A QUOTE